polypropylene packaging and packaging

The enterprise produces soft containers (Big Bags) of a wide variety of types with a carrying capacity of 500, 1000, 1500 kg with a safety factor of 5:1. We carry out a full technological cycle for the production of soft containers, from extrusion of polypropylene yarns and weaving of high-strength fabrics to cutting and tailoring finished products of the most diverse types.

In order to place an order for manufacturing you shall fill in thequestionnaire!

Polypropylene Woven Flat Bags are manufactured on modern equipment of the Austrian company “Starlinger”.

They are used for packaging of bulk products (sugar, groats, salt, mixed fodders, fertilizers, building materials, chemical products and others).

In order to place an order for manufacturing you shall fill in thequestionnaire!

Polypropylene Woven Laminated Block Bottom Bags (AD*STAR Type) are manufactured on modern equipment and by license of the Austrian company “Starlinger”.

A distinctive feature of AD*STAR® bags is that they are box-shaped, made of laminated polypropylene fabric and therefore have exceptional strength and resistance to moisture.

In order to place an order for manufacturing you shall fill in thequestionnaire!

Polypropylene Woven Leno / Mesh Bags are the most popular packaging material used for the storage, transportation, packaging and subsequent sale of products of agricultural and other industries (onions, potatoes, peppers, cabbage, carrots, beets, eggplants and other vegetables; toys and other piece goods; firewood for picnics) through the wholesale and retail networks.

Bags can be made of polypropylene yarns of red, blue, yellow, as well as other colors at the request of the customer. The top of the bag can be heat-cut or with sewn string. The bottom of the bag can be with a one-line or two-line seam.

In order to place an order for manufacturing you shall fill in thequestionnaire!

Basically, polypropylene fabric is used for making bags and soft containers, for sewing linerbags and innerliners for gondolas.

Polypropylene fabric is also widely used in other industries:.

- in agriculture – to protect cultural plantations from weeds and protect the soil from erosion, preserve moisture, prevent sudden temperature fluctuations in the early spring period; (See Agrotextile)

- in the process of furniture production;

- in the production process of bulk concrete floors in industrial buildings;

- while conducting repair work on the facades of buildings as wind insulation. (See Roofing Film)

In order to place an order for manufacturing you shall fill in thequestionnaire!

Agrotextile is a lightweight woven material that provides rapid growth, early maturation and a good harvest of vegetables and fruits. In addition, agrotextile inhibits the growth of weeds, protects plants from insects and birds and also protects plants from frost. Agrotextile is laid directly on the bed and does not require a frame structure. Perfectly passes water, air.

In order to place an order for manufacturing you shall fill in thequestionnaire!

Roofing film is made of polypropylene fabric which the laminate as a melt blend of polypropylene with polyethylene is applied by extrusion on one or both sides.

It has exceptional mechanical strength and elasticity.

Due to special additives it provides resistance to UV radiation for 3 to 6 months. After installation of the film the heat insulation and the roof structure will be protected from the effects of rainfall up to finish the installation of roofing.

LLC ‘Tandem LTD’ manufacrures films of two types:

- Waterproofing (Water Barrier);

- Vaporproofing (Vapor Barrier).

In order to place an order for manufacturing you shall fill in thequestionnaire!

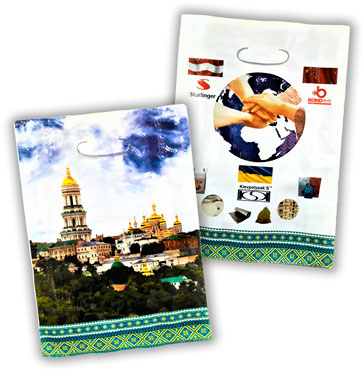

Customers are given the opportunity to choose what should be the printing and film:

Film:

- BOPP (or PET);

- matt or glossy.

Printing:

- flexographic or rotogravure;

- direct or reverse;

- one-sided or two-sided;

- full or partial printing area.

In order to place an order for manufacturing you shall fill in thequestionnaire!